3 Kinds of Plastic Injection Molding Materials

Are you looking to get plastic injection molding materials made? Perhaps you’re new to the world of manufacturing and wonder what you need. This process uses injected resin to create your parts.

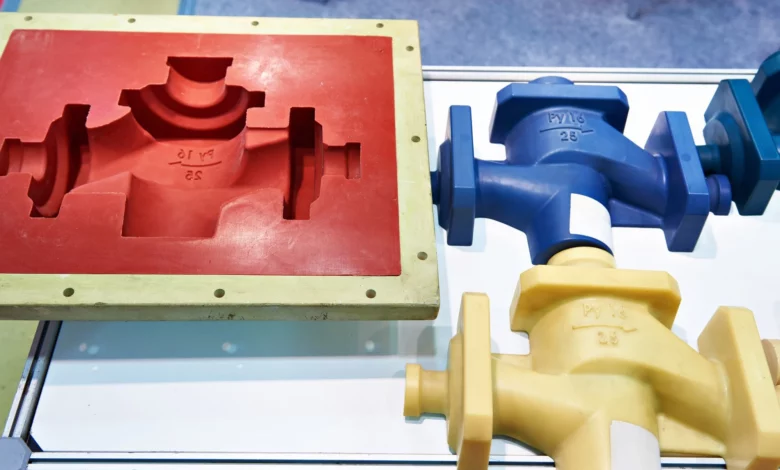

Molding is what happens with the resin, and the tool that makes the parts is known as a mold. This manufacturing process is becoming more and more popular. It’s also very flexible.

The world of 3D printing and plastic injection molding are compatible. You can even create an injection mold with a 3D printing process.

Wondering about the kinds of materials that you can use in this process? We’re going to take a look at everything you need to know. Keep reading to get the inside scoop on plastic injection molding.

1. ABS

ABS is an acronym for Acrylonitrile-Butadiene-Styrene. It is a kind of plastic that is commonly used for injection molding. ABS is a strong, lightweight material with good impact strength, and it provides high-temperature stability.

It is also cost-effective and is available in many colors. ABS is frequently used to make automotive and electronic parts, including components for laptops, cell phones, household appliances, toys, and sporting equipment.

The material is also used for medical equipment and low-cost consumer products. ABS provides a good balance of properties, making it appropriate for a wide range of applications.

2. Acetal

Acetal is a type of industrial plastic that is most commonly used for injection molding. It is a thermoplastic polymer made up of formaldehyde, also known as polyoxymethylene or POM. Acetal is rigid, strong, and resistant to heat and chemicals, making it an ideal material for use in a variety of industrial applications.

It is also lightweight and can easily be molded to fit into any desired shape. Acetal is widely used in automotive, medical, electrical, plumbing, food processing and packaging, and sporting goods industries due to its great properties. It is also widely used in the manufacture of bearings and other machine components for its superior strength and wear resistance.

3. Polyethylene

Polyethylene is a type of custom plastic injection molding material made from ethylene. It is the most common type of plastic used in the world and is very versatile due to its inertness, durability, and low cost. It can be found in many different products, from automotive parts to clothing.

Polyethylene is known for its excellent shock resistance, making it ideal for various injection molding applications. It also has great tensile strength, making it an excellent material for holding shapes. Finally, it is also non-toxic and chemical resistant, making it a safe material to use in products.

Learn These Injection Molding Materials Today

Plastic injection molding materials come in a variety of shapes, sizes, and types. The three most common are ABS, Acetal, and Polyethylene. Each has its own unique properties and is used for a wide range of applications.

To make the right choice for a project, it is important to know which plastic type to use. Consult a professional to choose the most appropriate type for your needs.

If you find this helpful and want to read more great content, check out our latest blog posts now!